innovate and develop solutions

However, electric mobility raises many issues around environmental impacts and pollution: extraction of ores, production of electricity and recycling of critical metals. The end-of-life of EV batteries focuses attention on these issues.

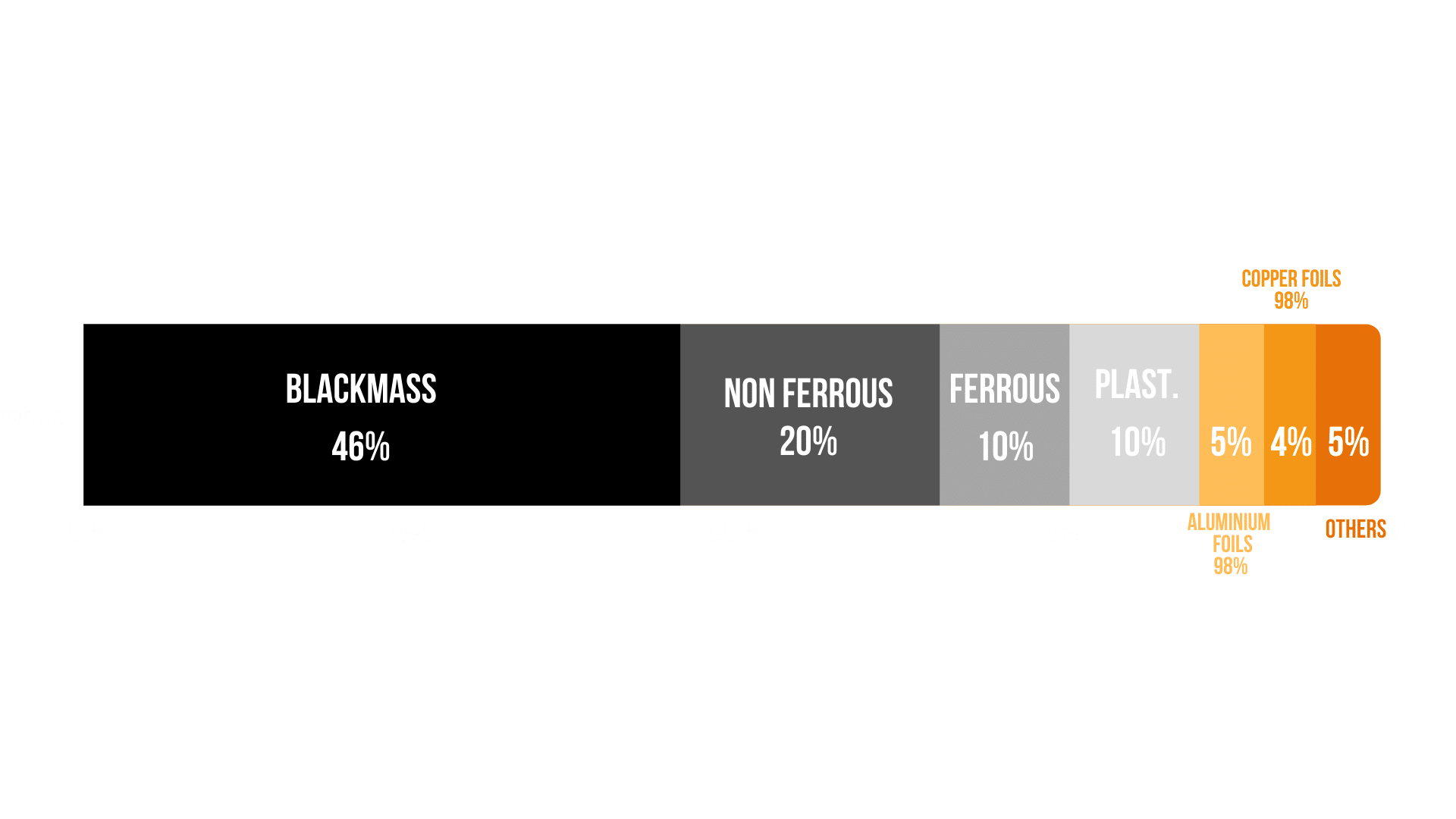

MTB is a responsible company that aims to become a pioneer in Zero Waste solutions for players who are concerned about transforming their waste into raw materials. Therefore, faced with the increase in lithium-ion battery production and in the lack of a high-performance treatment solution, MTB has developed an innovative and eco-efficient recycling solution.

To develop this solution, MTB’s R&D teams have worked alongside major battery manufacturers, EV collectors and dismantlers, players in the hydrometallurgy industry, academic laboratories, car manufacturers and French and European institutions.

Thanks to the many partners we work with and the complementary nature of our expertise, several industrial units have been set up to process production scrap or end-of-life batteries. Right from the process design stage, we have taken into account future technological developments in batteries.