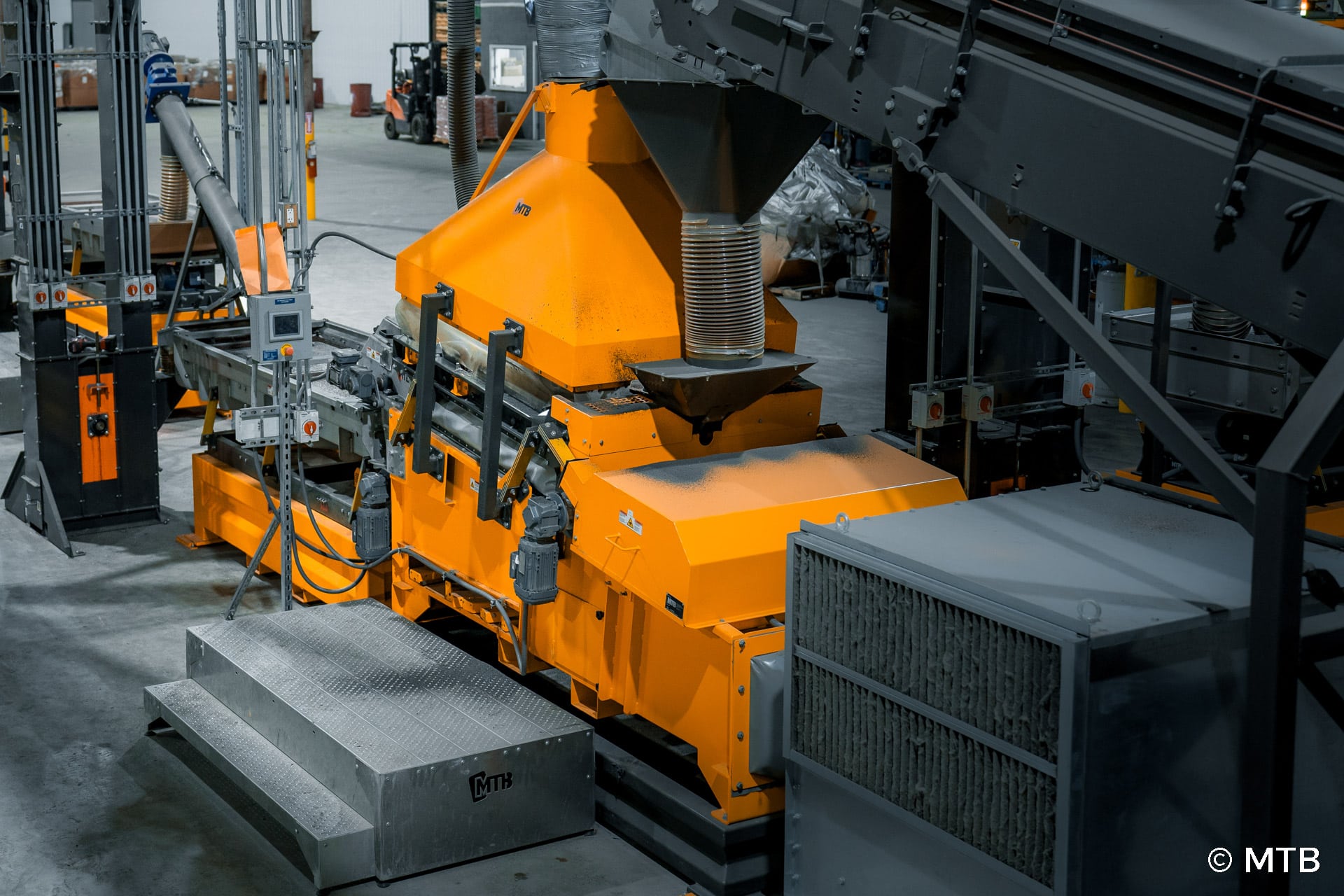

MTB densimetric tables provide efficient separation of granulated materials of homogeneous size and shape with large density differences.

Densimetric separation is achieved through the combination of a fluidized-air screen and an inclined vibrating table. This equipment excels in waste sorting, separating heavy metals, light metals and plastics, as well as in the purification of rubber granulates.

MTB vibrating screens are used to sort waste by size. They can be fitted with a metal sheet or a perforated sheet whose mesh size is determined according to the product. The screen can be easily changed in just a few minutes, thanks to a quick-release clamping system.

Our vibrating screens have proven their worth in cable recycling (final separation) and tire recycling (textile extraction). However, their ease of use makes them indispensable in many other fields.

TMR magnetic sorters consist of a horizontal conveyor equipped with a beater and a permanent-magnet overband. The combination of the two actions ensures efficient extraction of steel pieces from the shredded product.

The heights of the beater and overband can be adjusted to suit the product being processed. The TMR sorter can also be supplied with an optional second overband for optimum waste sorting in a single pass.

The SMB consists of an endless belt conveyor and a head-mounted magnetic pulley. It is a separator designed for the removal of fine fractions.

The belt’s high speed enables single-layer processing of large quantities of fines (up to 50 T/H for the SMB 2000). Combining this speed with the high magnetic force of the inductor, triple separation is achieved.

Massive” and inert materials (non-ferrous, glass, pebbles, etc.) are thrown as far as possible from the conveyor, while ferrous materials are collected at the rear of the separator, while ‘light’ materials, as well as wet and sticky particles, are collected at the front of the separator.

The EDX is an eddy current separator designed to extract non-ferrous metals from bulk product streams (WEEE, ASR, slag, etc.).