Actualités Engineering, Manufacturing

MTB diversifies to reach Zero Waste

9 April 2021

MTB diversifies to reach Zero Waste

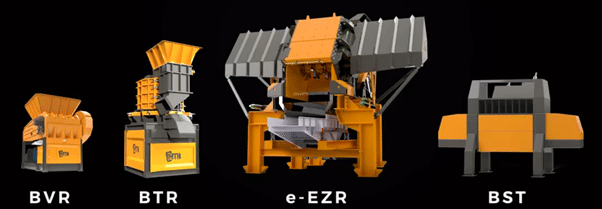

MTB long-term strategy is based on innovating and diversifying our recycling skills. The development of new solutions is made possible thanks to the versatility, the quality and the our equipment.