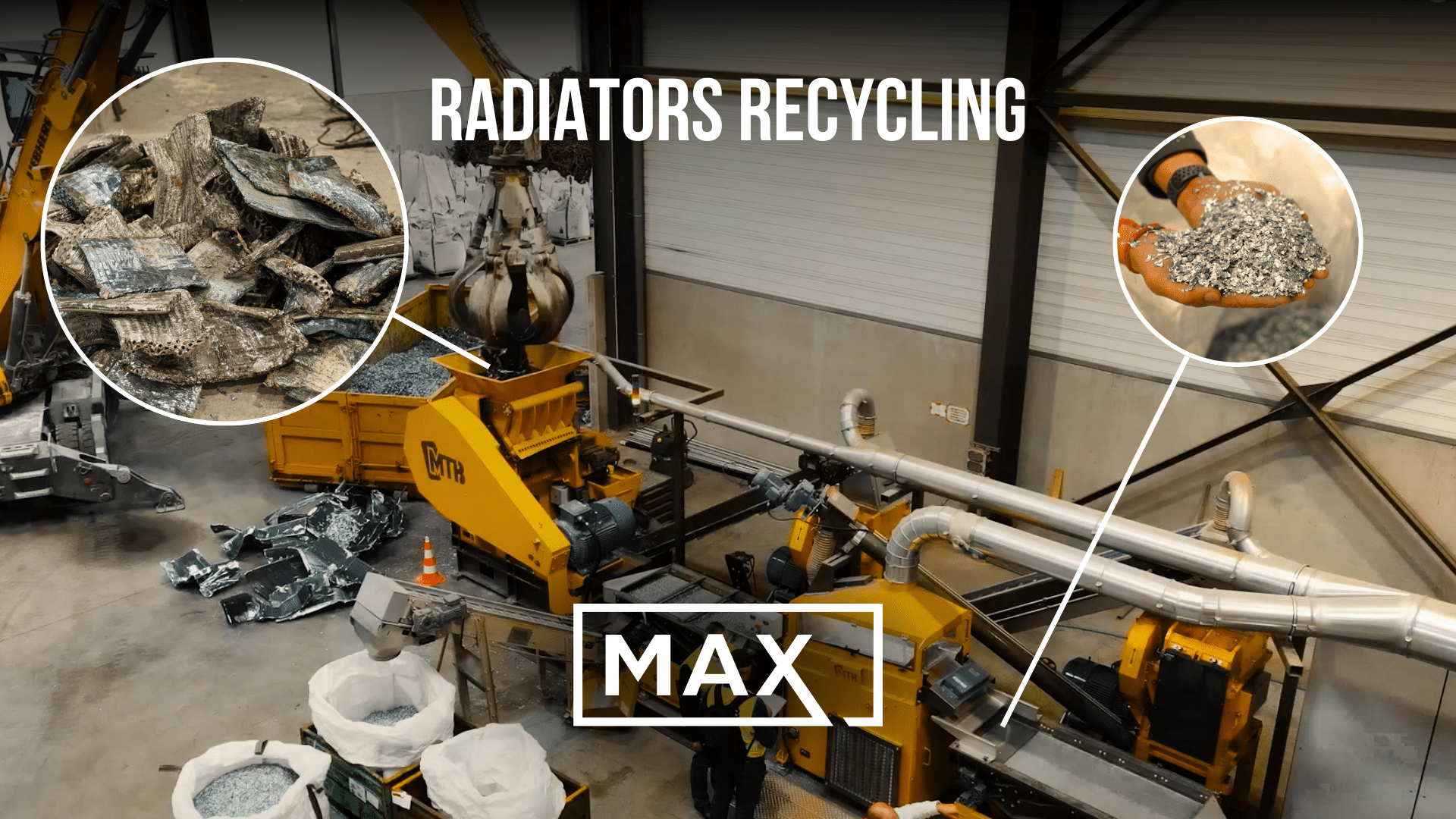

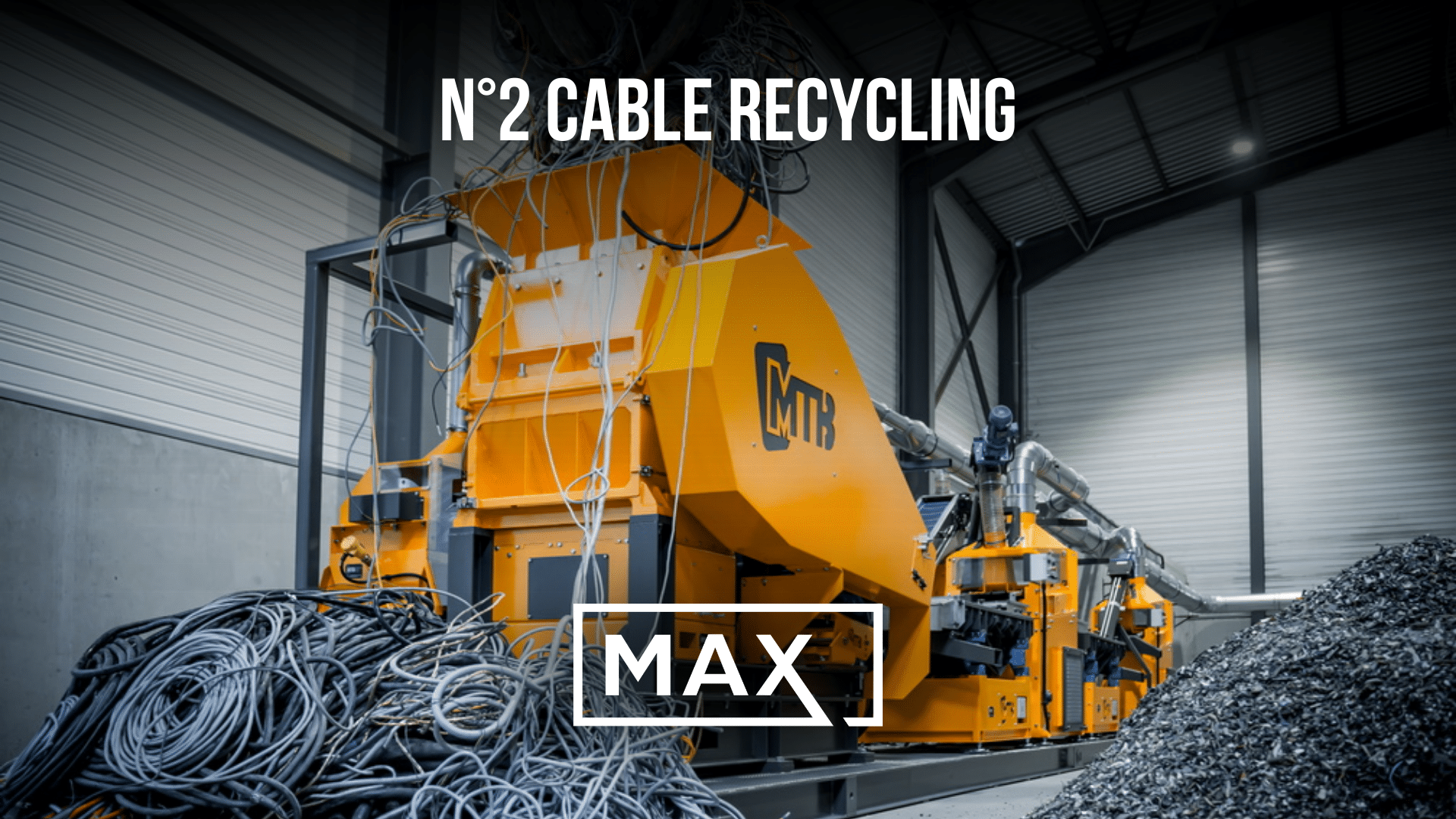

MaX is designed to meet the needs of companies of all sizes. Its lower cost and smaller dimensions do not compromise the renowned quality of our recycling machines.

This complete, compact industrial waste management line is an ideal solution for companies looking to optimize their space and investment while benefiting from state-of-the-art technology.

It can be integrated to complement an existing line or serve as a standalone recycling solution.