Équipements de recyclage Par Application Application

Équipements de recyclage Par Application Application

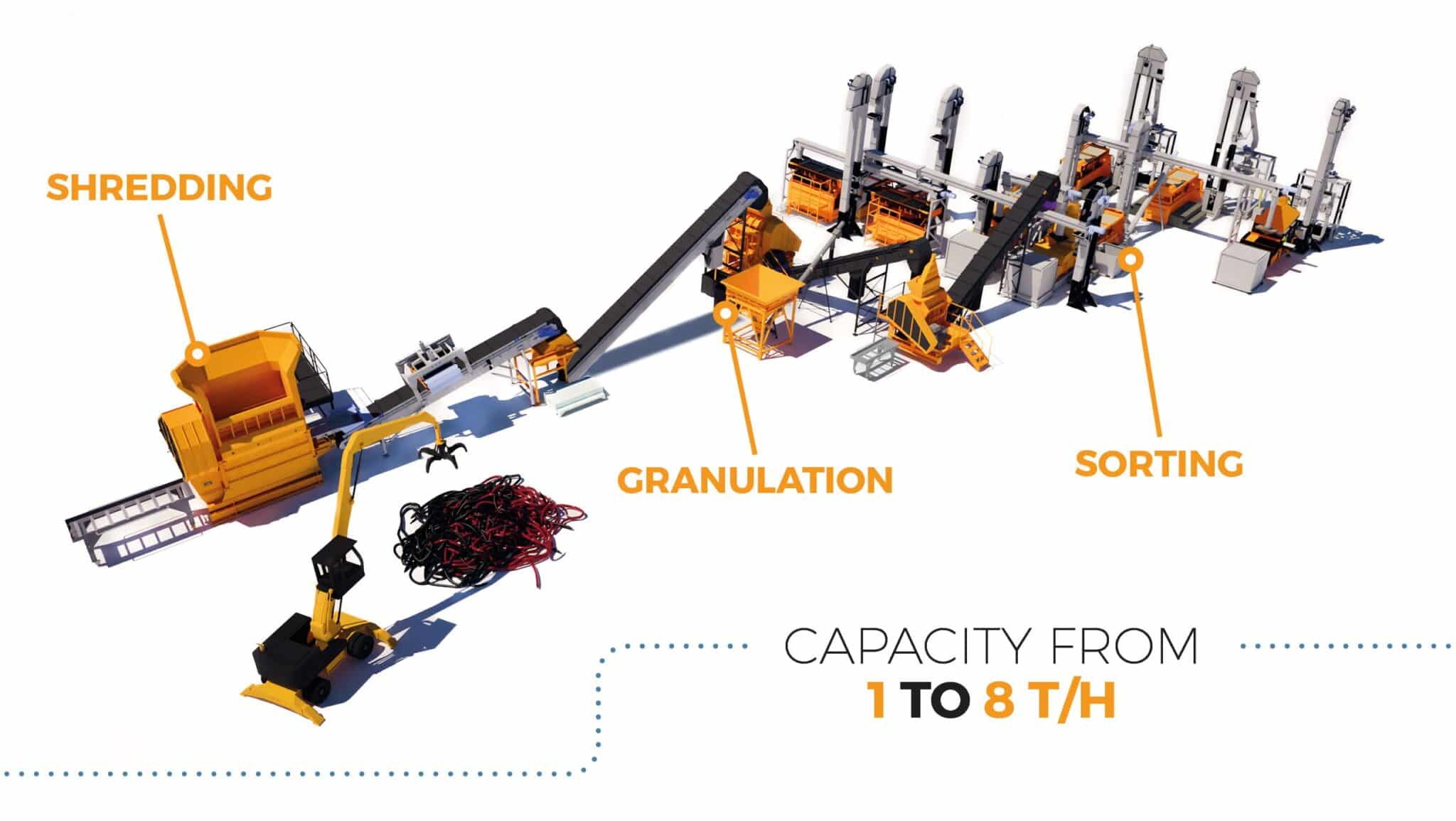

MTB Recycling offers high-performance equipment for cable recycling, including shredding, granulation and separation processes.

Our lines process various types of cable, such asc copper and aluminum, EHV, ACSR, automotive harnesses, etc., to recover valuable materials such as fine copper, copper and aluminum shot.

Thanks to our modular and customizable solutions, MTB guarantees efficient and environmentally-friendly recovery of industrial waste, meeting customers’ specific cable recycling requirements.

As both an operator and a manufacturer, MTB brings over 45 years of proven expertise in cable recycling.

Why trust us? Every MTB recycling machine is rigorously tested and optimized in our own recycling facility before being offered for sale.

Our proprietary process is designed to maximize the recovery of valuable materials contained in raw cables. This advanced recycling technique not only conserves non‑renewable natural resources such as copper and aluminum, but also significantly reduces the energy required for the extraction and transformation of these raw materials.

Our robust and powerful shredders can reduce materials up to 10 mm in a single pass, depending on the screen used.

This first stage also ensures the removal of ferrous scrap.

As a crucial part of the cable recycling process, granulation ensures a consistent particle size to optimize downstream separation and sorting operations.

Achieving sizes up to 3 mm.

Density separation is achieved through the combination of an air fluidized bed and an inclined vibrating table. Vibrating screens are then used for the final separation of products according to the size and shape of the materials.

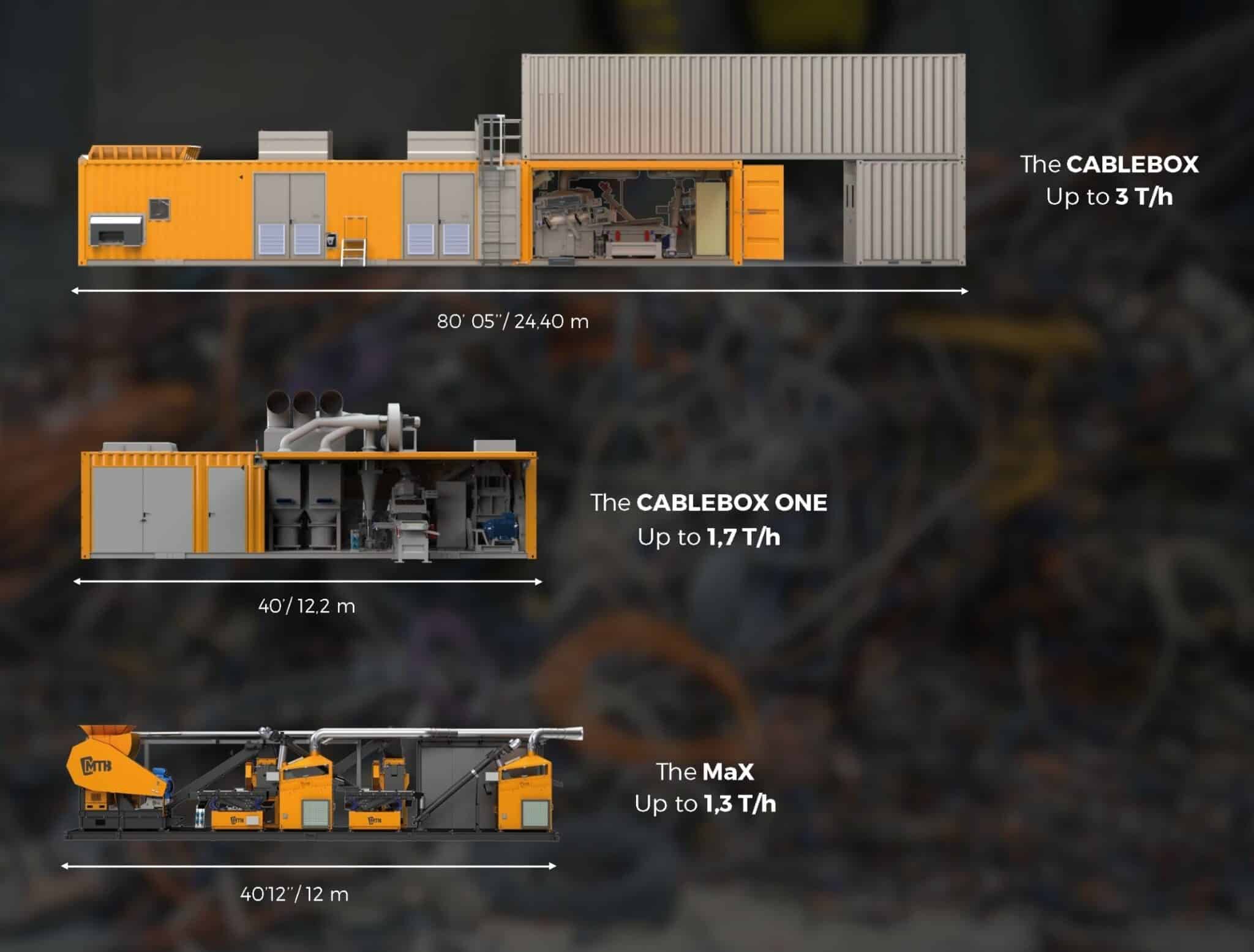

Ready‑to‑use, our BOX systems integrate a complete recycling line within assembled containers.

Compact, mobile, efficient, and cost‑effective, these systems retain all the equipment of a standard MTB recycling line while condensing it into containerized units.

Designed as Plug’n’Run concepts, they are delivered ready‑to‑use with minimal assembly required — only the connection of the containers. The equipment is easily transportable and allows for rapid commissioning.