Actualités

5 questions about aluminum recycling

6 July 2022

MTB’s Eric Fromont answers questions about processing aluminum scrap

RECYCLING TODAY – JUNE 2022

Actualités

6 July 2022

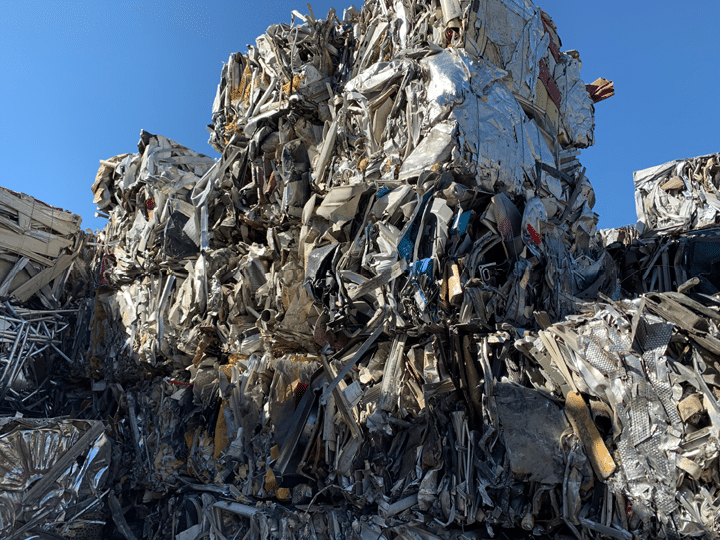

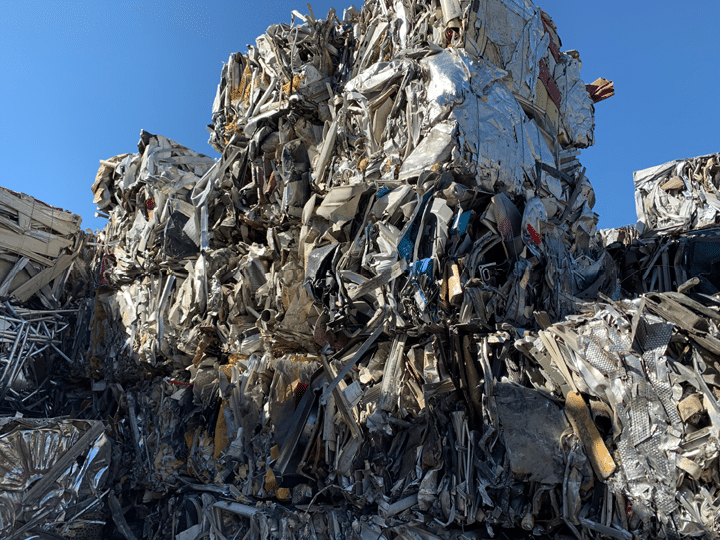

MTB offers numerous process solutions to handle aluminum scrap. In addition to aluminum cables, MTB has developed solutions to process aluminum bales, aluminum casting, aluminum profiles and mixed aluminum scrap.

Our engineering teams design recycling sequences composed of BDR shredders, BAT granulators and sorting equipment to reach purity rate of 99.99 percent.

Our new-generation EZR preshredders can open dense, clean aluminum sheet bales as well as contaminated aluminum waste from waste facilities. MTB’s reliable BDR processes clean aluminum cans, sheets or profiles. We developed the BTR vertical mills for contaminated material or big aluminum pieces. The BTR can process difficult aluminum scrap in batches with an ejection flap for shreddable at a rate of up to 15 tons per hour. Starting from 18 tons per hour, the MODULAR shredders from our exclusive partner Wendt Corp. are the perfect complementary equipment for higher productivity.

When MTB develops recycling concepts, two goals guide our decision to improve the profitability of our lines:

As an example, the zero waste line, started last year at our headquarters in France, was the first line to use an eDrive with synchronous electrical motors instead of a hydraulic drive for a preshredder. This step minimized the energy requirement by around 25 percent compared with the older generation of machine for the same productivity.

We are moving forward with serial production of equipment with eDrive. The results obtained are exceeding our expectations and confirming our long-term developments.

Recently, Wendt and Julien Curt sold an EZR eDrive in the U.S. The performance of the EZR allows its installation ahead of Wendt’s modular shredders.

More MTB shredder ranges with eDrive are in development, and one is being tested in a German recycling plant.